Back from the paint shop, ready for assembly.

Rear facia and doors were installed.

OEM carpet was stripped of sound deadner and padding and re-installed. Door had the glass, power windows and door panels re-installed.

Custom fabricated bulkheads for the master cylinders were installed.

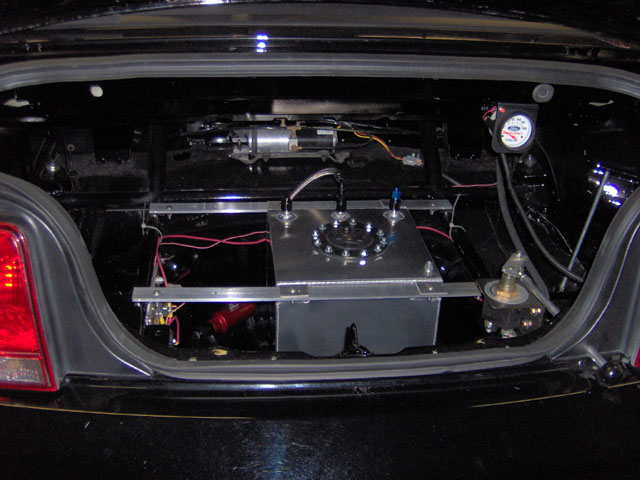

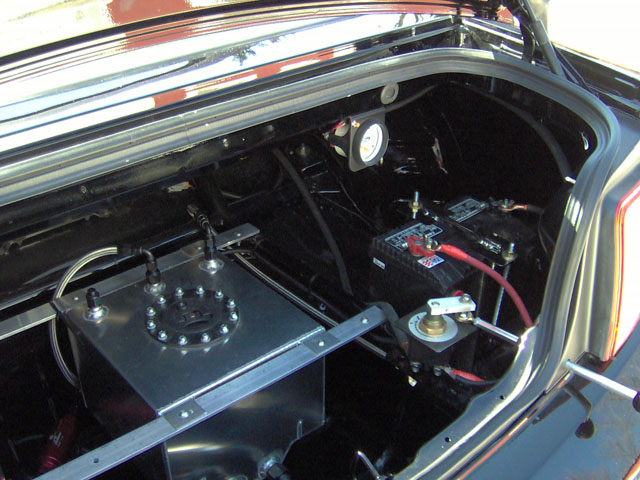

Trunk.

Rear antil roll bar. Standard equipment on all 2008 Cobra Jet Mustangs.

Heavy duty adjustable upper control arm with mounting bracket. Standard equipment on all 2008 Cobra Jet Mustangs.

Rear lower control arms. Standard equipment on all 2008 Cobra Jet Mustangs.

Nine Inch Ford rear end assembly. This is standard equipment in all 2008 Cobra Jet Mustangs. Features aluminum center section, spool and 35 spline Strange axles.

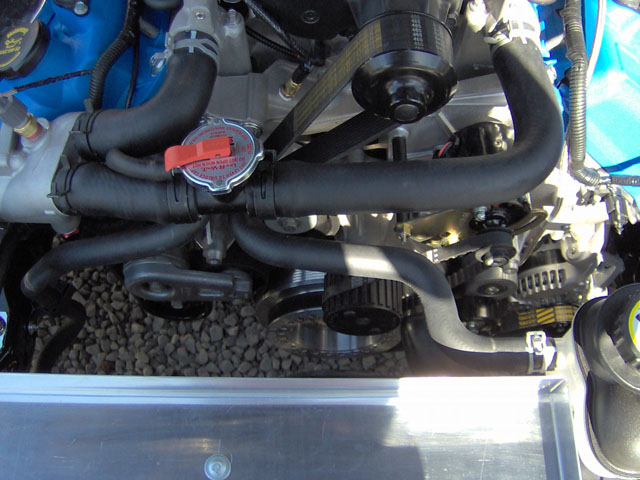

Front view of car with the engine installed for wiring and fuel system mach up.

Carpet in process of being fit to cover back seat area.

Fuel cell and volt meter installed in trunk.

Side view of car.

Side view of car.

Rear view of car.

Side view.

Side view.

Front view.

Ready to load up and go to Detroit Autorama.

Ready to load up and go to Detroit Autorama.

View of driver's side.

5.4 Liter supercharged engine.

Coolant tank to the right is for the intercooler. The OEM coolant tank for the radiator was removed and the top hose was split and a Moroso fill cap was used. Aluminum tool tray manufactured by Wydendorf Machine.

Overflow tank was eliminated for a inline radiator cap.

View of interior.

All Cobra Jet Mustangs have the battery located in the trunk.